How can plastic parts achieve lightweight design while ensuring strength?

Release Time : 2025-04-08

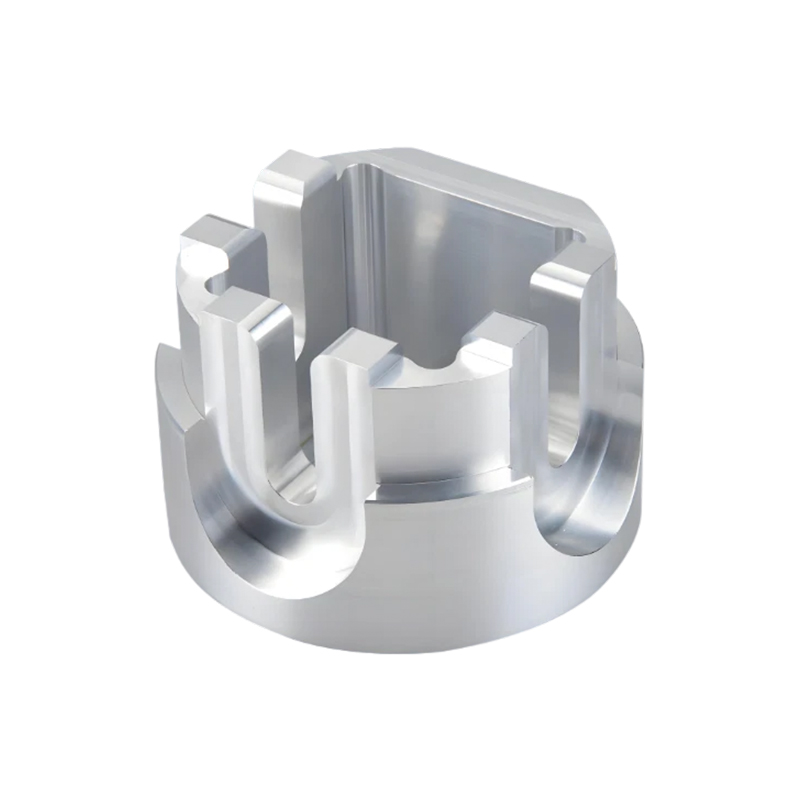

In modern manufacturing, plastic parts are increasingly used as machined parts because plastics can achieve significant lightweight design while ensuring sufficient strength. This feature not only meets the stringent requirements for product performance, but also brings unprecedented innovation opportunities to many industries.

First, plastic materials themselves have high specific strength, that is, high strength per unit weight. This means that even with relatively thin wall thickness design, plastic parts can still withstand large mechanical stress. For example, some high-performance engineering plastics such as polycarbonate (PC) and polyetheretherketone (PEEK) have excellent tensile and impact resistance and are widely used in automotive, aerospace and other fields. By carefully selecting the right plastic material, designers can significantly reduce the weight of parts without sacrificing strength, which is crucial for improving fuel efficiency or increasing the payload of aircraft.

Secondly, the design flexibility of plastic parts also makes it possible to achieve lightweight. Compared with metal materials, plastics can be manufactured into parts with complex shapes through various processing processes such as injection molding and extrusion molding. These parts often contain internal reinforcing rib structures or hollow parts, thereby reducing the amount of material while maintaining overall rigidity and strength. In addition, with the help of computer-aided design (CAD) software, engineers can accurately simulate the mechanical behavior of plastic parts under different design schemes and optimize the geometric structure to achieve the best strength-to-weight ratio. This design process based on simulation technology allows every detail to be carefully considered to ensure that the final product is both strong and lightweight.

Furthermore, the application of composite materials further enhances the strength of plastic parts and promotes the realization of lightweight goals. Embedding fiber-reinforced materials such as glass fiber and carbon fiber into a plastic matrix to form a composite material can greatly improve the overall performance of the material. This type of composite material not only inherits the excellent processing properties of plastics, but also performs well in strength, hardness and heat resistance. For example, carbon fiber reinforced plastic (CFRP) is widely used in high-end sports equipment, racing car bodies and even aviation due to its excellent strength-to-weight ratio. Using these advanced materials, manufacturers can significantly reduce weight without affecting product functionality, bringing better user experience and economic benefits.

It is worth noting that the surface treatment technology of plastic materials is also constantly improving its durability and aesthetics, indirectly supporting lightweight design. For example, by applying a wear-resistant coating or electroplating, the hardness and wear resistance of the plastic parts surface can be enhanced, and the service life can be extended. This makes the design scheme that originally did not dare to use plastic to replace metal due to concerns about insufficient strength a reality, further promoting the development of the lightweight trend.

Finally, with the increasing awareness of environmental protection, the lightweight design of plastic parts is also in line with the concept of green manufacturing. Lighter products have lower transportation costs and consume less energy, which helps to reduce carbon footprint. At the same time, many new plastic materials have good recyclability, which is conducive to resource recycling and promotes sustainable development. Therefore, in the long run, choosing plastic as machined parts can not only save costs for enterprises, but also contribute to the earth's environment.

In summary, plastic parts have achieved significant lightweight design while ensuring strength with their excellent material properties, flexible design potential, advanced composite technology and continuously improving surface treatment processes. Whether it is to improve energy efficiency, improve operating experience or respond to environmental protection calls, plastic parts are an attractive choice. In the future, with the development of new materials and technological advancement, we have reason to believe that plastic parts will show its unique charm in more fields and help all walks of life move towards a more efficient and sustainable future.

First, plastic materials themselves have high specific strength, that is, high strength per unit weight. This means that even with relatively thin wall thickness design, plastic parts can still withstand large mechanical stress. For example, some high-performance engineering plastics such as polycarbonate (PC) and polyetheretherketone (PEEK) have excellent tensile and impact resistance and are widely used in automotive, aerospace and other fields. By carefully selecting the right plastic material, designers can significantly reduce the weight of parts without sacrificing strength, which is crucial for improving fuel efficiency or increasing the payload of aircraft.

Secondly, the design flexibility of plastic parts also makes it possible to achieve lightweight. Compared with metal materials, plastics can be manufactured into parts with complex shapes through various processing processes such as injection molding and extrusion molding. These parts often contain internal reinforcing rib structures or hollow parts, thereby reducing the amount of material while maintaining overall rigidity and strength. In addition, with the help of computer-aided design (CAD) software, engineers can accurately simulate the mechanical behavior of plastic parts under different design schemes and optimize the geometric structure to achieve the best strength-to-weight ratio. This design process based on simulation technology allows every detail to be carefully considered to ensure that the final product is both strong and lightweight.

Furthermore, the application of composite materials further enhances the strength of plastic parts and promotes the realization of lightweight goals. Embedding fiber-reinforced materials such as glass fiber and carbon fiber into a plastic matrix to form a composite material can greatly improve the overall performance of the material. This type of composite material not only inherits the excellent processing properties of plastics, but also performs well in strength, hardness and heat resistance. For example, carbon fiber reinforced plastic (CFRP) is widely used in high-end sports equipment, racing car bodies and even aviation due to its excellent strength-to-weight ratio. Using these advanced materials, manufacturers can significantly reduce weight without affecting product functionality, bringing better user experience and economic benefits.

It is worth noting that the surface treatment technology of plastic materials is also constantly improving its durability and aesthetics, indirectly supporting lightweight design. For example, by applying a wear-resistant coating or electroplating, the hardness and wear resistance of the plastic parts surface can be enhanced, and the service life can be extended. This makes the design scheme that originally did not dare to use plastic to replace metal due to concerns about insufficient strength a reality, further promoting the development of the lightweight trend.

Finally, with the increasing awareness of environmental protection, the lightweight design of plastic parts is also in line with the concept of green manufacturing. Lighter products have lower transportation costs and consume less energy, which helps to reduce carbon footprint. At the same time, many new plastic materials have good recyclability, which is conducive to resource recycling and promotes sustainable development. Therefore, in the long run, choosing plastic as machined parts can not only save costs for enterprises, but also contribute to the earth's environment.

In summary, plastic parts have achieved significant lightweight design while ensuring strength with their excellent material properties, flexible design potential, advanced composite technology and continuously improving surface treatment processes. Whether it is to improve energy efficiency, improve operating experience or respond to environmental protection calls, plastic parts are an attractive choice. In the future, with the development of new materials and technological advancement, we have reason to believe that plastic parts will show its unique charm in more fields and help all walks of life move towards a more efficient and sustainable future.