What high-performance stainless steel materials are used in stainless steel parts to ensure corrosion resistance and mechanical strength?

Release Time : 2025-04-21

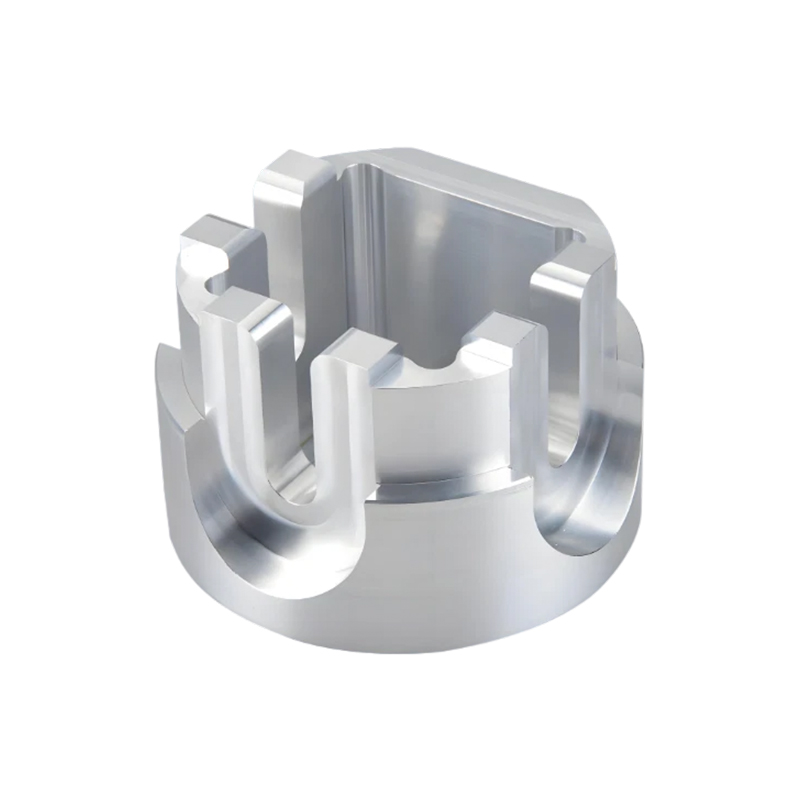

As an important component in modern industrial production, stainless steel parts play a key role in improving equipment performance, extending service life and ensuring safety. In order to ensure excellent corrosion resistance and mechanical strength, manufacturers have made many considerations and optimizations in material selection and process design.

First of all, 304 stainless steel is one of the most commonly used materials in stainless steel parts. This austenitic stainless steel is known for its good comprehensive properties and is widely used in food processing equipment, architectural decoration, chemical equipment and other fields. 304 stainless steel contains about 18% chromium and 8% nickel, which makes it have excellent corrosion resistance, especially in general atmospheric environment. In addition, 304 stainless steel also has good mechanical strength and weldability, and is suitable for a variety of processing methods such as cold rolling, hot rolling and machining.

Secondly, for applications requiring higher corrosion resistance and resistance to chloride stress corrosion cracking, 316 stainless steel is an ideal choice. In addition to 16% chromium and 10% nickel, 316 stainless steel also contains 2-3% molybdenum, which significantly improves its corrosion resistance in chloride-containing environments. Therefore, 316 stainless steel is often used in marine engineering, chemical equipment, pharmaceutical industry, and medical equipment. Its high strength and good toughness also make it a reliable material for long-term use under complex working conditions.

Furthermore, some high-end stainless steel parts use duplex stainless steel (such as 2205) to further improve performance. Duplex stainless steel combines the advantages of austenite and ferrite, with higher yield strength and better pitting resistance. This type of material not only provides excellent corrosion resistance in harsh environments, but also effectively resists stress corrosion cracking, and is particularly suitable for equipment working under extreme conditions such as oil and gas extraction and seawater desalination devices.

In order to further improve the comprehensive performance of stainless steel parts, many manufacturers will work hard on surface treatment. Common surface treatment methods include polishing, electroplating or sandblasting. For example, mirror polishing can not only improve the appearance quality of parts, but also significantly enhance their corrosion resistance; while sandblasting can improve the wear resistance and adhesion of parts to a certain extent, and is suitable for applications that require higher surface roughness.

It is worth noting that in order to ensure the performance of stainless steel parts in actual applications, manufacturers will conduct a series of rigorous tests and verifications. From raw material inspection to finished product sampling testing, every link strictly implements the internationally accepted quality management system. For example, by conducting multiple experiments such as salt spray test, tensile strength test and hardness test on samples, the actual performance of the product can be fully understood, and potential problems can be discovered in time for improvement. This not only improves the overall quality of the product, but also provides users with a reliable use experience.

In addition to the material itself, advanced manufacturing processes are also important factors in ensuring the high quality of stainless steel parts. For example, precision machining technology and automated production equipment can greatly improve production efficiency and product quality. These technologies can not only ensure that the dimensional tolerance and form and position tolerance of parts meet strict standards, but also avoid errors and defects that may be caused by manual operation. In addition, precision welding and packaging technology can ensure the sealing and protection level of parts, and prevent external contaminants from entering and affecting performance.

Finally, strict environmental standards are also an important part of the entire production process. Many manufacturers are committed to reducing the use of hazardous substances in the production process, such as heavy metals such as lead, mercury and cadmium, to ensure that products comply with relevant environmental regulations such as RoHS (Restriction of the Use of Certain Hazardous Substances Directive). In addition, the recyclability and low-energy design of stainless steel parts have also become the focus of more and more manufacturers, promoting green manufacturing and sustainable development.

In summary, by using high-performance 304, 316 stainless steel and other innovative materials, stainless steel parts can provide excellent corrosion resistance and mechanical strength in various application scenarios. Whether in food processing equipment, medical devices or other fields, it is an ideal choice to ensure efficient production. With the advancement of technology and the application of new materials, we are expected to see more innovative products in the future to provide users with a more perfect use experience.

First of all, 304 stainless steel is one of the most commonly used materials in stainless steel parts. This austenitic stainless steel is known for its good comprehensive properties and is widely used in food processing equipment, architectural decoration, chemical equipment and other fields. 304 stainless steel contains about 18% chromium and 8% nickel, which makes it have excellent corrosion resistance, especially in general atmospheric environment. In addition, 304 stainless steel also has good mechanical strength and weldability, and is suitable for a variety of processing methods such as cold rolling, hot rolling and machining.

Secondly, for applications requiring higher corrosion resistance and resistance to chloride stress corrosion cracking, 316 stainless steel is an ideal choice. In addition to 16% chromium and 10% nickel, 316 stainless steel also contains 2-3% molybdenum, which significantly improves its corrosion resistance in chloride-containing environments. Therefore, 316 stainless steel is often used in marine engineering, chemical equipment, pharmaceutical industry, and medical equipment. Its high strength and good toughness also make it a reliable material for long-term use under complex working conditions.

Furthermore, some high-end stainless steel parts use duplex stainless steel (such as 2205) to further improve performance. Duplex stainless steel combines the advantages of austenite and ferrite, with higher yield strength and better pitting resistance. This type of material not only provides excellent corrosion resistance in harsh environments, but also effectively resists stress corrosion cracking, and is particularly suitable for equipment working under extreme conditions such as oil and gas extraction and seawater desalination devices.

In order to further improve the comprehensive performance of stainless steel parts, many manufacturers will work hard on surface treatment. Common surface treatment methods include polishing, electroplating or sandblasting. For example, mirror polishing can not only improve the appearance quality of parts, but also significantly enhance their corrosion resistance; while sandblasting can improve the wear resistance and adhesion of parts to a certain extent, and is suitable for applications that require higher surface roughness.

It is worth noting that in order to ensure the performance of stainless steel parts in actual applications, manufacturers will conduct a series of rigorous tests and verifications. From raw material inspection to finished product sampling testing, every link strictly implements the internationally accepted quality management system. For example, by conducting multiple experiments such as salt spray test, tensile strength test and hardness test on samples, the actual performance of the product can be fully understood, and potential problems can be discovered in time for improvement. This not only improves the overall quality of the product, but also provides users with a reliable use experience.

In addition to the material itself, advanced manufacturing processes are also important factors in ensuring the high quality of stainless steel parts. For example, precision machining technology and automated production equipment can greatly improve production efficiency and product quality. These technologies can not only ensure that the dimensional tolerance and form and position tolerance of parts meet strict standards, but also avoid errors and defects that may be caused by manual operation. In addition, precision welding and packaging technology can ensure the sealing and protection level of parts, and prevent external contaminants from entering and affecting performance.

Finally, strict environmental standards are also an important part of the entire production process. Many manufacturers are committed to reducing the use of hazardous substances in the production process, such as heavy metals such as lead, mercury and cadmium, to ensure that products comply with relevant environmental regulations such as RoHS (Restriction of the Use of Certain Hazardous Substances Directive). In addition, the recyclability and low-energy design of stainless steel parts have also become the focus of more and more manufacturers, promoting green manufacturing and sustainable development.

In summary, by using high-performance 304, 316 stainless steel and other innovative materials, stainless steel parts can provide excellent corrosion resistance and mechanical strength in various application scenarios. Whether in food processing equipment, medical devices or other fields, it is an ideal choice to ensure efficient production. With the advancement of technology and the application of new materials, we are expected to see more innovative products in the future to provide users with a more perfect use experience.