Is the design of steel parts easy to assemble and adjust?

Release Time : 2025-03-27

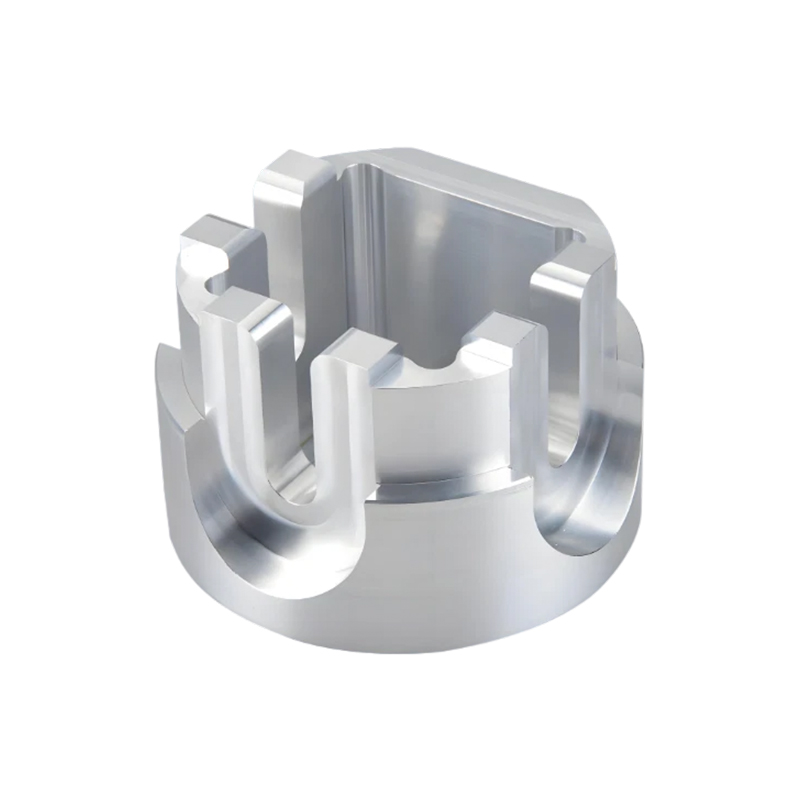

The design of steel parts occupies a pivotal position in the field of mechanical manufacturing. It is not only related to the functionality and durability of the parts, but also directly affects the assembly efficiency and adjustment flexibility of the entire equipment. A well-designed steel part can greatly simplify the assembly process, improve production efficiency, and show convenience in subsequent maintenance and adjustment, which is crucial to improving the performance and user experience of the overall equipment.

When designing steel parts, the first consideration is the standardization and modularization of parts. By adopting standard sizes and universal interfaces, the interchangeability between parts can be ensured, the need for customized parts can be reduced, thereby speeding up assembly and reducing assembly errors. Modular design further promotes the flexible combination of parts, allowing the equipment to quickly adjust the configuration according to different application scenarios without having to adapt each part one by one, greatly improving assembly efficiency.

In addition, designers also need to pay attention to the easy assembly characteristics of parts. This includes reasonable tolerance control to ensure that the parts are neither too tight to make assembly difficult nor too loose to affect stability. Using easy-to-operate connection methods, such as threaded connections and snap-on designs, can simplify assembly steps, reduce tool use, and improve the work efficiency of assembly workers. At the same time, considering the weight and volume of the parts, the reasonable design of the handling and positioning structure, such as handles and positioning holes, can help reduce the labor intensity of assembly and ensure assembly accuracy.

In terms of adjustability, the design of steel parts should reserve sufficient adjustment space and adjustment mechanism. For example, by designing adjustable support structures or fastening devices, the parts can be fine-tuned according to the actual operating conditions after assembly to achieve the best working state. This design not only improves the adaptability and flexibility of the equipment, but also provides convenience for subsequent maintenance and upgrades.

It is worth mentioning that the application of modern manufacturing technologies such as CAD/CAM (computer-aided design and manufacturing) has brought revolutionary changes to the design of steel parts. With the help of these technologies, designers can perform precise simulated assembly and adjustment tests in a virtual environment, discover and solve potential assembly problems in advance, and further optimize the design plan. This not only shortens the product development cycle, but also ensures the high quality and efficiency of part design.

In summary, the design of steel parts needs to take into account both functionality and the convenience of assembly adjustment. Through standardized and modular design, the enhancement of easy assembly characteristics, and the reservation of adjustment mechanisms, efficient coordination between parts and equipment can be achieved. With the continuous advancement of technology, the design of steel parts will be more intelligent and flexible in the future, providing strong support for the transformation and upgrading of the manufacturing industry.

When designing steel parts, the first consideration is the standardization and modularization of parts. By adopting standard sizes and universal interfaces, the interchangeability between parts can be ensured, the need for customized parts can be reduced, thereby speeding up assembly and reducing assembly errors. Modular design further promotes the flexible combination of parts, allowing the equipment to quickly adjust the configuration according to different application scenarios without having to adapt each part one by one, greatly improving assembly efficiency.

In addition, designers also need to pay attention to the easy assembly characteristics of parts. This includes reasonable tolerance control to ensure that the parts are neither too tight to make assembly difficult nor too loose to affect stability. Using easy-to-operate connection methods, such as threaded connections and snap-on designs, can simplify assembly steps, reduce tool use, and improve the work efficiency of assembly workers. At the same time, considering the weight and volume of the parts, the reasonable design of the handling and positioning structure, such as handles and positioning holes, can help reduce the labor intensity of assembly and ensure assembly accuracy.

In terms of adjustability, the design of steel parts should reserve sufficient adjustment space and adjustment mechanism. For example, by designing adjustable support structures or fastening devices, the parts can be fine-tuned according to the actual operating conditions after assembly to achieve the best working state. This design not only improves the adaptability and flexibility of the equipment, but also provides convenience for subsequent maintenance and upgrades.

It is worth mentioning that the application of modern manufacturing technologies such as CAD/CAM (computer-aided design and manufacturing) has brought revolutionary changes to the design of steel parts. With the help of these technologies, designers can perform precise simulated assembly and adjustment tests in a virtual environment, discover and solve potential assembly problems in advance, and further optimize the design plan. This not only shortens the product development cycle, but also ensures the high quality and efficiency of part design.

In summary, the design of steel parts needs to take into account both functionality and the convenience of assembly adjustment. Through standardized and modular design, the enhancement of easy assembly characteristics, and the reservation of adjustment mechanisms, efficient coordination between parts and equipment can be achieved. With the continuous advancement of technology, the design of steel parts will be more intelligent and flexible in the future, providing strong support for the transformation and upgrading of the manufacturing industry.