In what specific application scenarios can steel parts give full play to their wear resistance?

Release Time : 2025-01-28

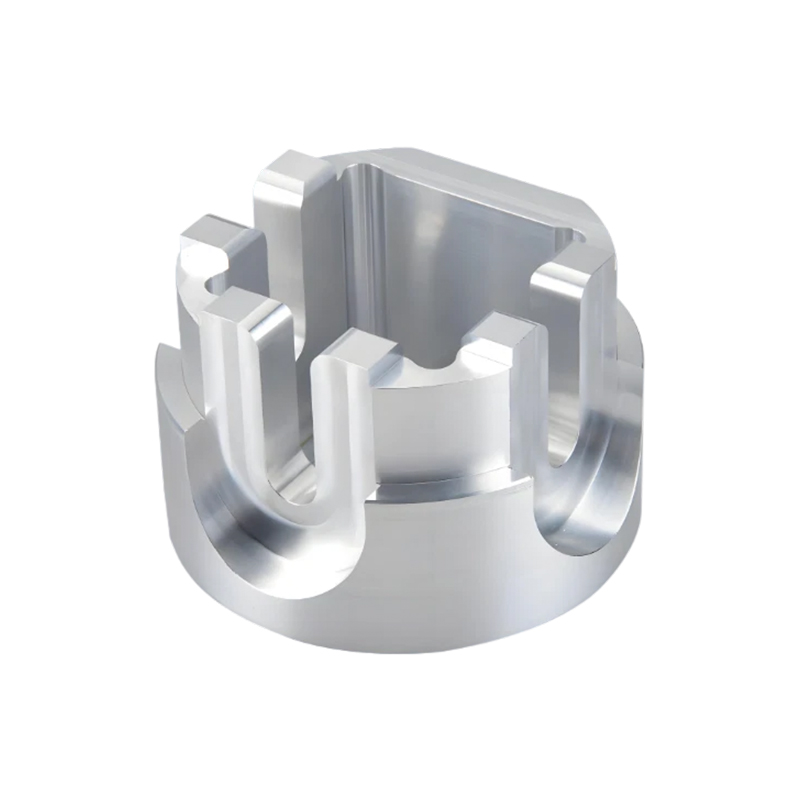

Steel parts, with their high strength, high precision, and excellent wear and corrosion resistance, play a vital role in many industrial fields. Especially in some application scenarios with extremely high requirements for material performance, steel parts have shown their irreplaceable advantages.

In the field of mechanical manufacturing, the high strength characteristics of steel parts enable them to withstand huge pressure and impact force, and are not easy to deform or break. For example, key components such as machine tool transmission shafts, bearings, and gears are mostly made of high-strength steel to ensure the stability and durability of machine tools at high speeds. In addition, in heavy machinery and engineering equipment, such as excavators and cranes, steel parts are also widely used due to their excellent load-bearing capacity and wear resistance.

The aerospace field has extremely stringent requirements on materials, and steel parts have become an indispensable part of this field with their high strength and excellent corrosion resistance. In the manufacture of aircraft, rockets and other aircraft, steel parts are used to make various structural parts and connectors to ensure the safety performance of aircraft in extreme environments. Especially in engine parts that are subjected to high temperature, high pressure and strong corrosion, the application of high-strength steel is particularly important.

In the automotive manufacturing industry, steel parts also play a key role. The wheels, frames, engine parts and brake system parts of automobiles all need to have high strength and wear resistance to ensure the driving safety and durability of automobiles under various road conditions. With the continuous development of the automotive industry, the performance requirements for steel parts are also constantly increasing, such as lightweight, high strength, high toughness, etc., to meet more stringent emission standards and energy efficiency requirements.

In addition, in the construction industry, steel parts are also widely used in the manufacture of key parts such as steel structures, bridges, and pipelines. Especially in some large public buildings and infrastructure projects, the high strength and corrosion resistance of steel parts have become an important guarantee for ensuring the quality and safety of the project.

In summary, steel parts can give full play to their high strength and wear resistance in specific application scenarios such as machinery manufacturing, aerospace, automobile manufacturing and construction, providing strong support for the development of various industries. With the advancement of science and technology and the upgrading of industry, the performance and application areas of steel parts will continue to expand and innovate.

In the field of mechanical manufacturing, the high strength characteristics of steel parts enable them to withstand huge pressure and impact force, and are not easy to deform or break. For example, key components such as machine tool transmission shafts, bearings, and gears are mostly made of high-strength steel to ensure the stability and durability of machine tools at high speeds. In addition, in heavy machinery and engineering equipment, such as excavators and cranes, steel parts are also widely used due to their excellent load-bearing capacity and wear resistance.

The aerospace field has extremely stringent requirements on materials, and steel parts have become an indispensable part of this field with their high strength and excellent corrosion resistance. In the manufacture of aircraft, rockets and other aircraft, steel parts are used to make various structural parts and connectors to ensure the safety performance of aircraft in extreme environments. Especially in engine parts that are subjected to high temperature, high pressure and strong corrosion, the application of high-strength steel is particularly important.

In the automotive manufacturing industry, steel parts also play a key role. The wheels, frames, engine parts and brake system parts of automobiles all need to have high strength and wear resistance to ensure the driving safety and durability of automobiles under various road conditions. With the continuous development of the automotive industry, the performance requirements for steel parts are also constantly increasing, such as lightweight, high strength, high toughness, etc., to meet more stringent emission standards and energy efficiency requirements.

In addition, in the construction industry, steel parts are also widely used in the manufacture of key parts such as steel structures, bridges, and pipelines. Especially in some large public buildings and infrastructure projects, the high strength and corrosion resistance of steel parts have become an important guarantee for ensuring the quality and safety of the project.

In summary, steel parts can give full play to their high strength and wear resistance in specific application scenarios such as machinery manufacturing, aerospace, automobile manufacturing and construction, providing strong support for the development of various industries. With the advancement of science and technology and the upgrading of industry, the performance and application areas of steel parts will continue to expand and innovate.