What weight advantages do machined aluminum parts have over parts made of other materials?

Release Time : 2025-01-13

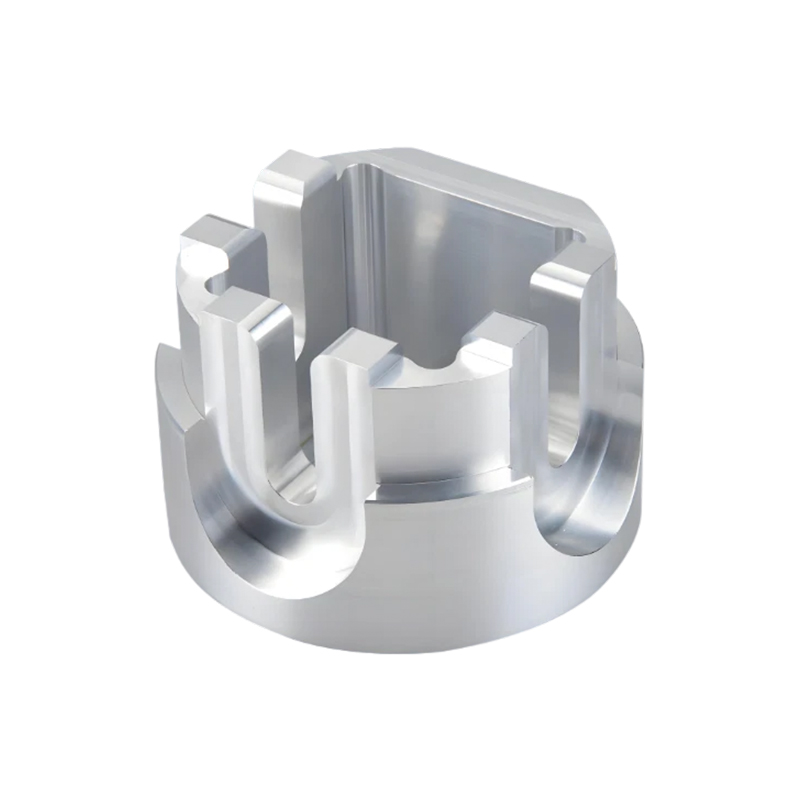

In the machining industry, aluminum parts have obvious weight advantages compared to other common materials such as steel, copper, stainless steel, etc.

1. Low density

Weight comparison: Assuming a part has the same geometry and volume, an aluminum part weighs only about one-third of a steel part and about one-quarter of a copper part.

2. Lightweight design

Automotive and Aerospace: In the automotive and aerospace sectors, lightweight design is key. Aluminum parts can significantly reduce the weight of the entire vehicle or aircraft, thereby improving fuel efficiency and flight performance and reducing energy consumption.

Sports Equipment: In sports equipment (such as bicycles, golf clubs, etc.), aluminum parts can improve the portability and comfort of the equipment.

3. Balance between strength and weight

Aluminum Alloys: By adding alloying elements (such as magnesium, copper, zinc, etc.), the strength of aluminum can be significantly improved, making it comparable to some steels while maintaining a lower density.

4. Processing performance

Easy processing: Aluminum has good processing performance and is easy to perform operations such as cutting, milling, and drilling, and can produce parts with complex shapes.

Surface treatment: Aluminum can be treated by anodizing, electroplating and other surface treatments to improve corrosion resistance and aesthetics while maintaining its lightweight advantage.

5. Cost-effectiveness

Material cost: Aluminum is relatively cheap, and due to its light weight, the amount of material used can be reduced, thereby reducing manufacturing costs.

Transportation cost: As aluminum parts are light in weight, transportation cost is also reduced accordingly, especially in large-scale production and transportation, this advantage is particularly obvious.

6. Environmentally friendly

Recycling: Aluminum is a highly recyclable material. The process of recycling aluminum consumes little energy and its performance is almost unaffected after recycling. Using aluminum parts helps reduce resource consumption and environmental pollution.

The weight advantage of machined aluminum parts mainly comes from its low density, good processing performance and the use of high-strength alloys. These properties make aluminum parts widely used in fields that require lightweight design (such as automobiles, aerospace, sports equipment, etc.). Through reasonable design and processing, aluminum parts can meet the requirements of high strength and corrosion resistance while maintaining a low weight, thereby improving the overall performance and cost-effectiveness of the product.

1. Low density

Weight comparison: Assuming a part has the same geometry and volume, an aluminum part weighs only about one-third of a steel part and about one-quarter of a copper part.

2. Lightweight design

Automotive and Aerospace: In the automotive and aerospace sectors, lightweight design is key. Aluminum parts can significantly reduce the weight of the entire vehicle or aircraft, thereby improving fuel efficiency and flight performance and reducing energy consumption.

Sports Equipment: In sports equipment (such as bicycles, golf clubs, etc.), aluminum parts can improve the portability and comfort of the equipment.

3. Balance between strength and weight

Aluminum Alloys: By adding alloying elements (such as magnesium, copper, zinc, etc.), the strength of aluminum can be significantly improved, making it comparable to some steels while maintaining a lower density.

4. Processing performance

Easy processing: Aluminum has good processing performance and is easy to perform operations such as cutting, milling, and drilling, and can produce parts with complex shapes.

Surface treatment: Aluminum can be treated by anodizing, electroplating and other surface treatments to improve corrosion resistance and aesthetics while maintaining its lightweight advantage.

5. Cost-effectiveness

Material cost: Aluminum is relatively cheap, and due to its light weight, the amount of material used can be reduced, thereby reducing manufacturing costs.

Transportation cost: As aluminum parts are light in weight, transportation cost is also reduced accordingly, especially in large-scale production and transportation, this advantage is particularly obvious.

6. Environmentally friendly

Recycling: Aluminum is a highly recyclable material. The process of recycling aluminum consumes little energy and its performance is almost unaffected after recycling. Using aluminum parts helps reduce resource consumption and environmental pollution.

The weight advantage of machined aluminum parts mainly comes from its low density, good processing performance and the use of high-strength alloys. These properties make aluminum parts widely used in fields that require lightweight design (such as automobiles, aerospace, sports equipment, etc.). Through reasonable design and processing, aluminum parts can meet the requirements of high strength and corrosion resistance while maintaining a low weight, thereby improving the overall performance and cost-effectiveness of the product.